GasShield® HiFlow™ Sandwich Filter

Ultra-Compact, High-Purity Filtration for ALD and Advanced Materials Processes

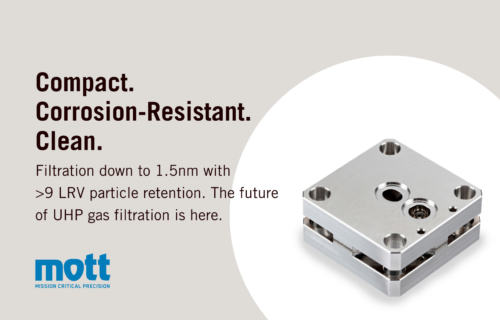

The GasShield® HiFlow™ Sandwich Filter is the first-ever point-of-use metal fiber filter engineered for ultra-high purity (UHP) gas delivery in cutting-edge semiconductor fabrication. Its compact, patent-pending design handles the extreme demands of Atomic Layer Deposition (ALD) and More-than-Moore architectures – delivering breakthrough flow performance without compromising particle retention or reliability.

Questions? Call 860.747.6333 Today!

Why Switch to the GasShield® HiFlow™ Sandwich Filter?

- Pressure Drop vs. Throughput: Traditional filters restrict flow — Mott’s design delivers 25% lower pressure drop, improving throughput without sacrificing performance.

- Particle Capture vs. Placement: Most filters miss particles where it counts — Mott provides >9 LRV retention down to 1.5nm right at the chamber, minimizing defects.

- Performance vs. Footprint: High-performance filters are often too bulky — Mott’s compact sandwich-style design fits in tight spaces without compromise.

GasShield® HiFlow™ Sandwich Filter Cut Sheet | Mott Corporation

Download the cut sheet for Mott’s GasShield® HiFlow™ Sandwich Filter—compact design, >9 LRV at 1.5nm, and low pressure drop for ALD and UHP gas delivery.

High Purity Surface Mount Flow Restrictors

The Mott GSMR Series flow restrictors support the 1.125” high-flow C-Seal configuration gas systems.

Product Specs

| How It Compares to Other Filters |

|

||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Features |

>9 LRV Filtration Efficiency Ultra-Compact Design Lower Pressure Drop All-Metal Construction Exceptional Thermal Stability |

||||||||||||||||||

| Applications |

|

||||||||||||||||||

| Performance Specifications |

|

||||||||||||||||||

| Ordering Information |

W-Seal and custom fittings available upon request. |

||||||||||||||||||

| Dimensions |

|

||||||||||||||||||

| Ready to Test It in Your Tool? |

Videos & Articles

FAQs

Q. What makes the GasShield® HiFlow™ Sandwich Filter different from other UHP filters?

It’s the industry’s first point-of-use metal fiber filter in a compact sandwich design. With a low-pressure drop, zero media migration, and unmatched filtration efficiency, it’s optimized for high-demand processes like ALD and More-than-Moore device nodes.

Q. What particle size does it retain?

The GasShield® HiFlow™ Sandwich Filter retains particles down to 0.0015 µm (1.5 nanometers).

It features Mott’s proprietary all-metal porous media, delivering exceptional sub-micron particle capture without sacrificing flow rate—perfect for the precision required in ALD and advanced semiconductor processes.

Q. Is it compatible with corrosive or reactive gases?

Yes. The filter’s all-metal construction (316L stainless steel or nickel options) ensures compatibility with a wide range of ultra-high purity process gases, including reactive and corrosive gases used in advanced semiconductor manufacturing.

Q. What is the pressure rating and temperature tolerance?

The GasShield® HiFlow™ Sandwich Filter is engineered for high-performance applications with the following specifications:

-

Maximum Operating Pressure:

750 psig (51.7 barg) -

Maximum Operating Temperature for Inert Gas: 460°

- Maximum Differential Pressure: 1000 psid (68.9 bar)

These ratings ensure the filter’s reliability and efficiency in ultra-high purity gas delivery systems, even under demanding conditions.

Q. How do I know what filter size or configuration I need?

contact us for more information