Categories

Avoiding the Next Brand Crisis: How Mott Powers Process Control and Industrial Automation

When process control breaks down, everything else follows.

When process control breaks down, everything else follows.

In today’s high-performance manufacturing industry, whether you’re building satellites, scaling clean energy platforms, or producing sterile pharmaceuticals, a single, small failure in the process can have catastrophic effects on safety, compliance, output, and your brand.

When Brand Crises Start on the Factory Floor

Recent high-profile process failures show what’s at stake:

- Boeing faced renewed FAA scrutiny in 2024 after multiple aircrafts reported missing bolts and structural defects, delaying delivery and damaging their reputation.

- Tesla recalled over 2 million vehicles due to quality and software issues, many linked to process control failures in the automated assembly line and sensor calibration.

- Abbott Nutrition’s 2022 baby formula recall sparked national shortages when contaminated product was traced to lapses in environmental controls and monitoring for dangerous microbes.

In each case, the process broke down before the product ever did. Each brand paid the ultimate price for cutting corners with lost revenue, trust, and lives.

Process Control Isn’t Just a Tactic—It’s a Strategic Advantage

Today’s manufacturers must balance their manufacturing process between performance, safety, regulatory compliance, and brand protection. The best process design enables that balance, which varies across different industries:

- In oil & gas, effective leak detection can mean the difference between uptime and disaster.

- In pharma and medtech, trace gas testing ensures produces safe and effective drug packaging.

- In food and bioprocessing, real-time sampling prevents yield loss and quality.

What do all these businesses have in common? They are among the thousands of applications serviced by Mott. Our team has spent over 65 years obsessively engineering customized filters and fluid flow products.

The combined design expertise of the Mott team, powered by cutting edge technology, is unmatched. When cheaper options from other companies fail due to clogging, cracking, or flow deviation, our partners come back, seeking ironclad reliability they can trust.

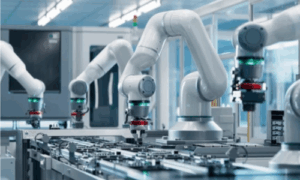

Your Automation is Only as Smart as the Components Inside It

Automation is accelerating across every sector. But automating a flawed process creates more failures, faster. Bolts go missing, doors swing open midflight, and lives are jeopardized. That’s where Mott’s industrial automation solutions come in. Our engineered components are crucial: the tiny, sometimes microscopic pieces of the whole major automation systems. These parts:

- Precisely regulate gas or fluid flow in real time

- Enhance purity control to prevent product loss

- Protect sensors and valves from contamination

- Enable inline quality monitoring to detect deviations before they fail

Our dynamic applications and experience range from gas mixing in semiconductor fabs to pressure control in chemical plants. Mott’s filtration and flow technologies allow automated systems to operate with accuracy and consistency, without sacrificing quality.

Scaling from Prototype to Production Without Surprises

It’s a common story: the prototype works perfectly until you scale. Without real-time feedback loops, statistical process control (SPC), and a reliable partner, it’s easy to miss these small faults before they interrupt the whole process. A miscalibration turns into millions of your product yanked back from consumers. Faith in your well established company collapses before your eyes. Although it is a simple error, the results are devastating, and the result is inexcusable.

Mott implements several six sigma-quality controls at multiple checkpoints to catch the fallacy before it replicates on a mass scale. Our modern technology digitally tracks upper and lower specs for key parameters.

Utilizing 3D printing, we handle complex geometries and porous-solid integration in a single part. Automation requires tighter tolerances, so our additive platforms (like Renishaw and Velo3D) let you design for performance first before scaling confidently.

The Backbone of Industry

Mott is no longer just building products, we’re a national necessity. We exist on many of the key manufacturing processes you haven’t heard of, and some you have. We strengthen the domestic supply chain with our advanced porous metal components, regulating flow at the micro level.

Whether you’re sparging oxygen into a bioreactor, flowing xenon into a propulsion unit, or managing hazardous gases in semiconductor fabs, Mott’s critical components maintain the integrity of automation systems.

Our promise has remained a constant, an unwavering commitment to our customers: we deliver products crafted with the highest reliability in the world, delivered with the best lead times, and with great value.