Continuous Emissions Monitoring

Continuous Emissions Monitoring Systems (CEMS) are essential for real-time measurement of regulated air pollutants—ensuring compliance with environmental regulations like EPA Part 60/75, EU directives, and local mandates.

Why It Matters:

- Ensures regulatory compliance

- Protects downstream analyzers from fouling

- Prevents unplanned downtime

- Enables accurate, real-time emissions data

Questions? Call 860.747.6333 Today!

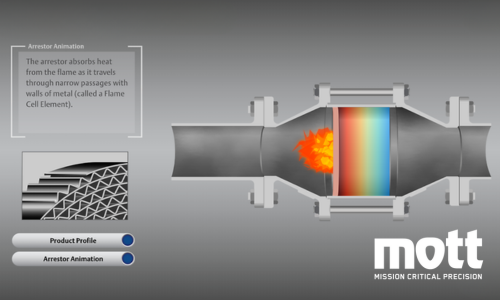

Mott's CEMS Filtration Solutions

Built to Perform in Harsh Environments:

Mott’s sintered porous metal filters are trusted across power plants, incineration facilities, cement kilns, chemical refineries, and steel manufacturing.

Our Solutions Include:

- Inertial gas sampling filters – Sub-micron particle removal

- Flow restrictors – Precise flow control for analyzers

- Diffusion elements – Gas conditioning before analysis

- Inline sintered filters – High-temp, corrosion-resistant design

IGS Filter Overview

Inertial Gas Sampling (IGS) filters collect particle-free samples from virtually any gas stream, particularly those operating at high temperatures, or which are heavily contaminated.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Reliable Filtration Solutions for Continuous Emissions Monitoring

Accurate emissions monitoring is critical for compliance, public health, and process safety. Mott’s Inertial Gas Sampling (IGS) filters are engineered to capture fine particulates in high-temperature gas streams—protecting analyzers, reducing downtime, and ensuring data integrity.

With over 65 years of expertise, Mott delivers U.S.-made filtration solutions trusted across industries for reliable, long-term CEMS performance.

Product Specs

| Application |

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material |

Stainless steel, Hastelloy, Inconel, Monel, other alloys |

||||||||||||

| Micron rating |

0.2 – 100+ µm depending on process requirements |

||||||||||||

| Operating temperature |

Operating temperatures up to 1000 deg F |

||||||||||||

| Flow rate |

Air/gas flow rate ranges in SCFM or SLPM depending on filter type |

||||||||||||

| Filter formats |

Disc, tube, cartridge, custom shape (list the formats offered) |

||||||||||||

| Cleaning method |

Backflushable / clean-in-place (CIP) / ultrasonic cleaning |

||||||||||||

| Connection Styles |

Tube Stub, Compression Fitting, ANSI Flanges and more. |

||||||||||||

| Certifications |

ASME, ISO 9001, ATEX, UL, CSA, CE, RoHS |

||||||||||||

Testimonials

Client Testimonial

“After switching to Mott filters, our CEMS analyzers required 60% fewer cleanings. Uptime improved dramatically, and we passed every compliance audit.”

— Environmental Manager, Waste-to-Energy Facility

Protect Your CEMS Systems

When it comes to Continuous Emissions Monitoring, the right filtration makes all the difference. Mott filters act as a first line of defense, capturing fine particulates to protect analyzers and maintain data accuracy. Without proper filtration, systems risk frequent cleanings, inaccurate readings, and non-compliance. With Mott, you get cleaner analyzers, reduced maintenance, improved uptime, and consistent performance that keeps you aligned with EPA and global standards.

Contact Us

FAQs: Continuous Emissions Monitoring

Q: What does an Inertial Gas Sampling (IGS) filter do in a CEMS system?

A: Mott’s IGS filters capture particulate matter in high-temperature, contaminated gas streams before they reach sensitive analyzers. This protects system accuracy, reduces instrument fouling, and minimizes maintenance downtime—making them essential to emissions compliance.

Q: What makes Mott’s filters different from others on the market?

A: Mott’s filters are sintered from high-grade porous metal and engineered for harsh stack environments. Unlike disposable or off-the-shelf options, they’re cleanable, customizable, and built to last—delivering consistent performance in high-heat and corrosive conditions.

Q: Can these filters be used in any CEMS setup?

A: Yes. Mott IGS filters are available in multiple configurations to fit a variety of CEMS designs. Our engineering team can also support custom integrations to ensure seamless retrofits or upgrades to existing monitoring systems.

Q: What industries use Mott filters for emissions monitoring?

A: Our filters are used across power generation, cement manufacturing, petrochemical refining, waste incineration, and more. Wherever continuous emissions monitoring is required, Mott delivers reliability.

Q: How often do these filters need to be cleaned or replaced?

A: Cleaning frequency depends on process conditions, but Mott filters are designed to be reusable and maintain their integrity over multiple cycles. Many customers report significantly reduced service intervals after switching to Mott.

Q: How do I choose the right IGS filter for my application?

A: Our team will evaluate your process conditions—such as gas composition, temperature, flow rate, and regulatory requirements—to recommend the optimal filter solution. You can also start by downloading our filter sizing guide or contacting an engineer.