Browse Products

Our experienced engineers and porous technologies have helped customers solve challenging technical problems for over 60 years. If you don’t find what you need by browsing our products, feel free to contact us directly to inquire about customized components developed in our Customer Innovation Center. Our project teams are eager to collaborate with you.

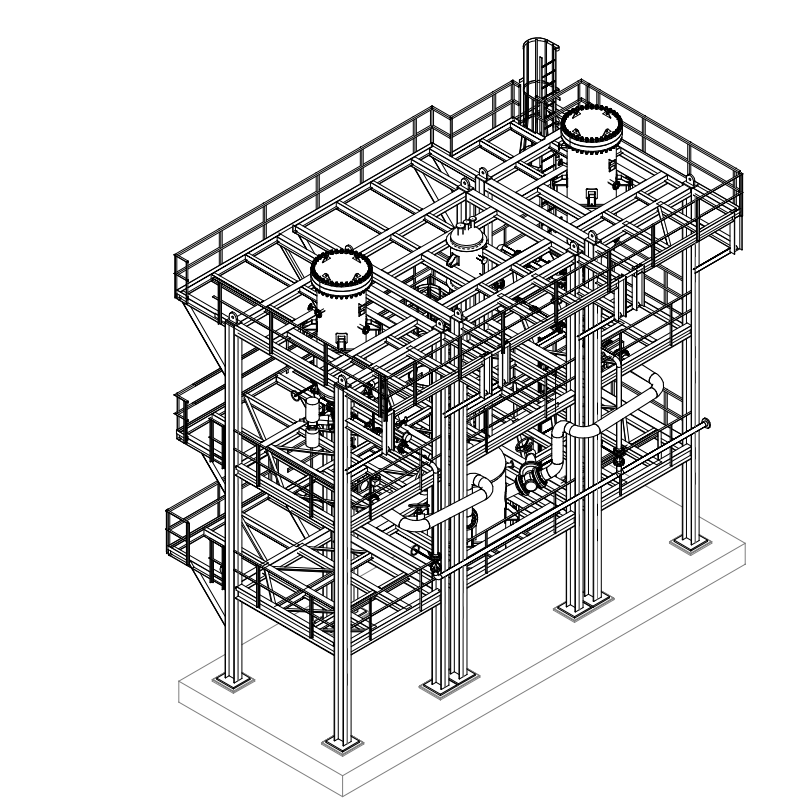

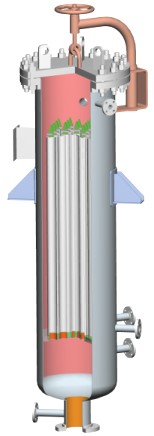

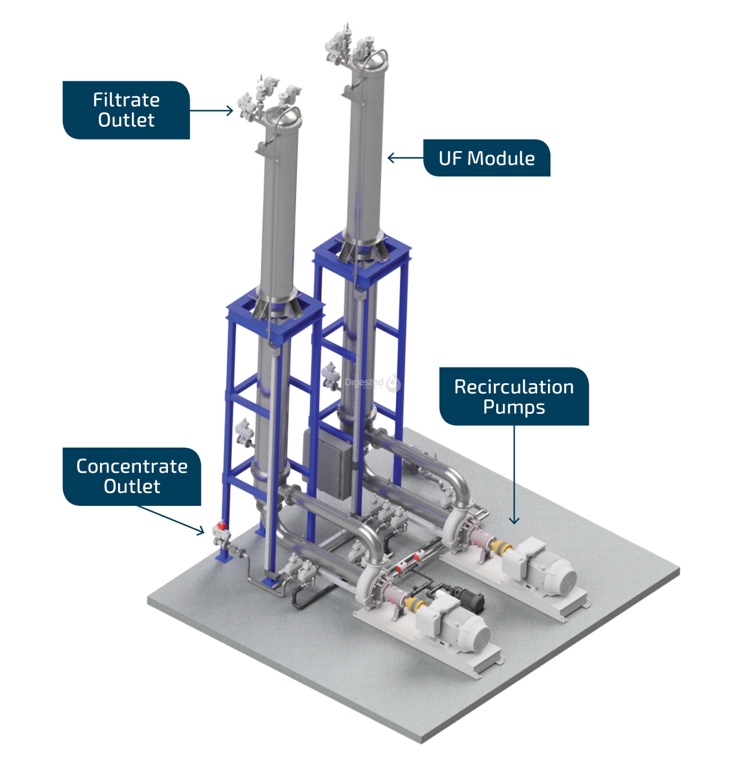

- Process Filters, Skids and Elements

- Water Reclamation System

- Industrial Filter Cartridges

- High Purity Filters & Components

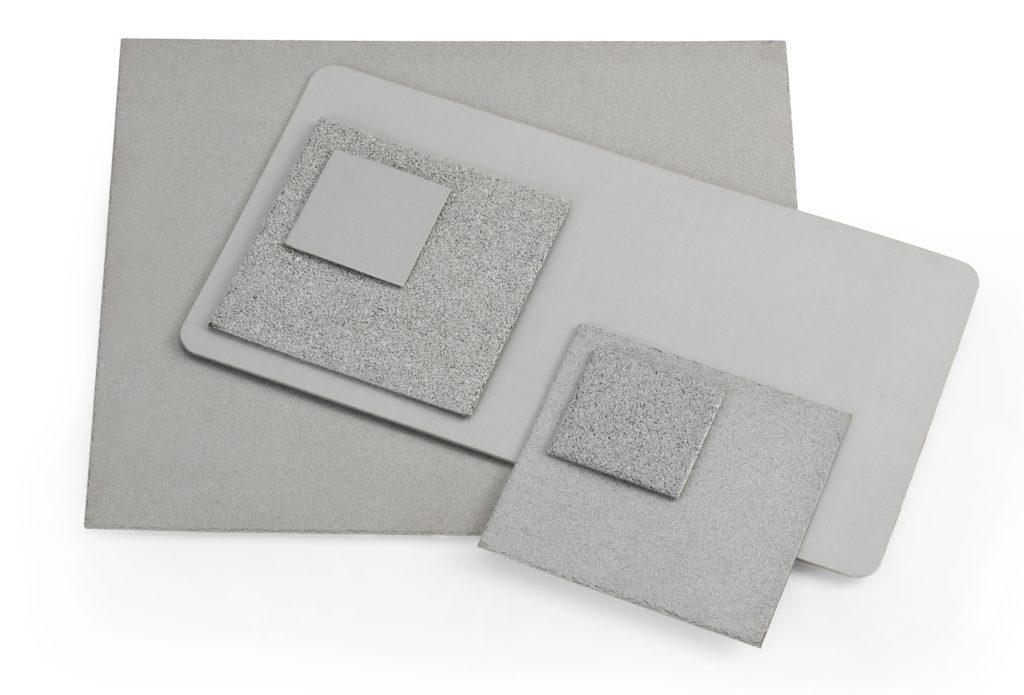

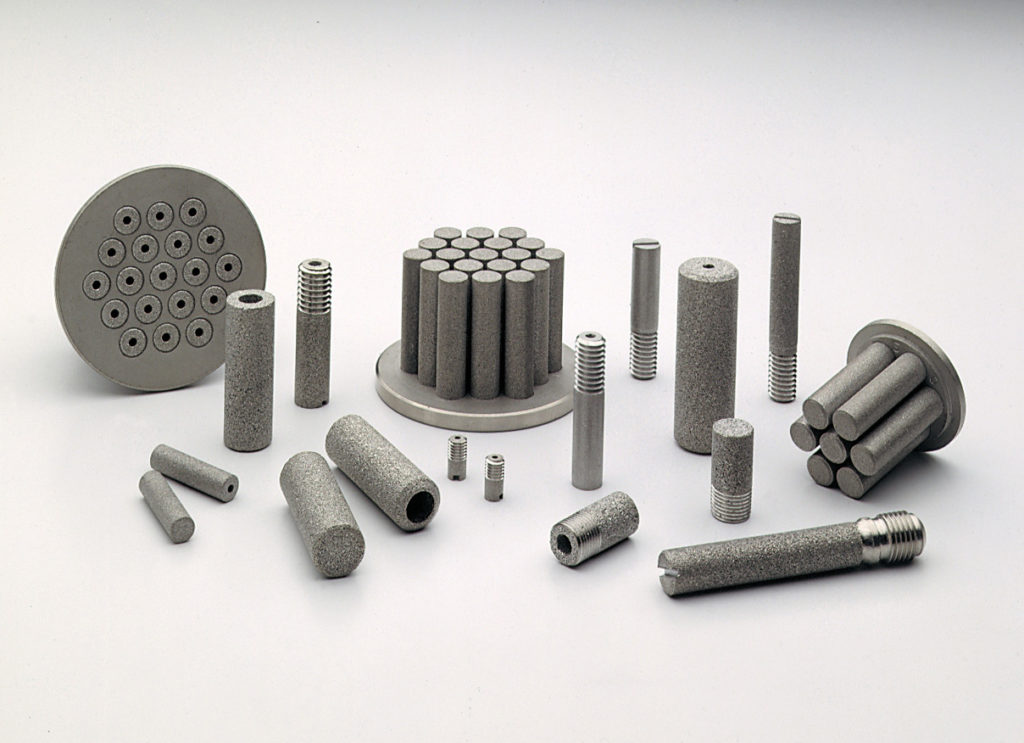

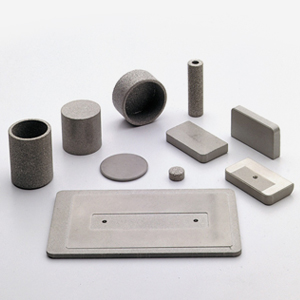

- Filter Assemblies and Porous Components

- Frit Assemblies and Lab Filters

- Industrial Gas Flow Restrictors

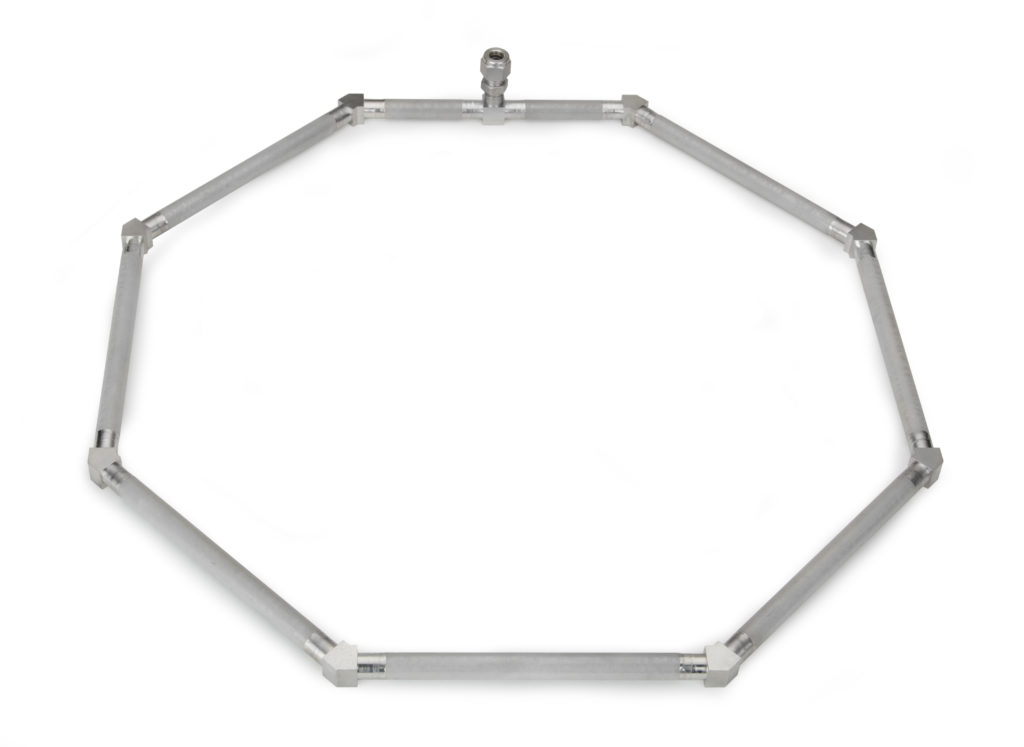

- Industrial Sparger Systems

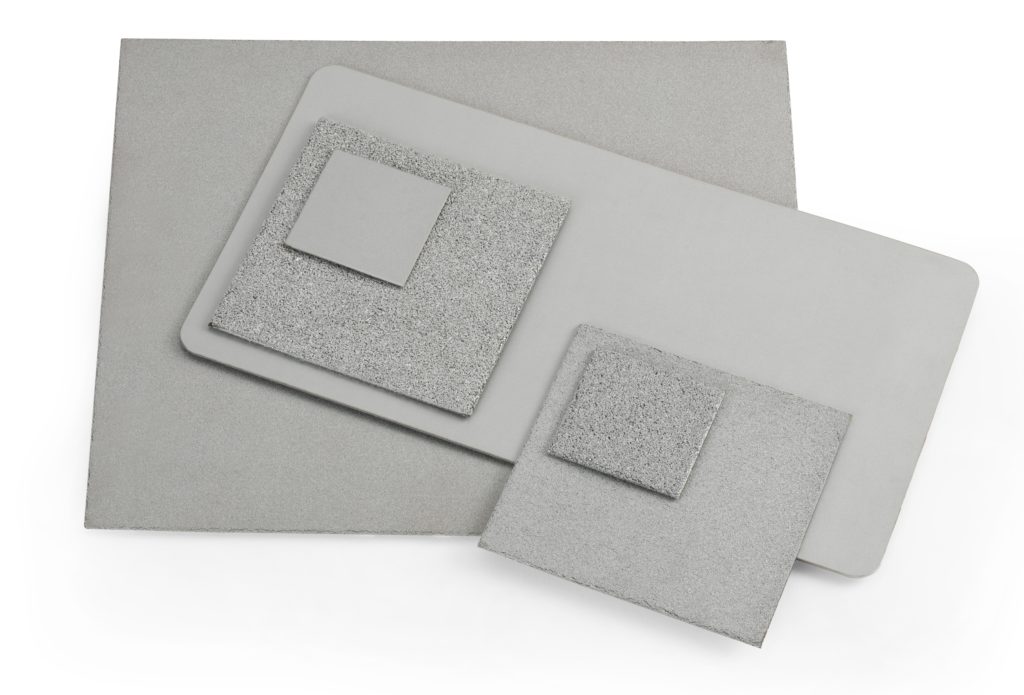

- Gas Diffusion & Transport Layers

- Flame Arrestor Products

- Sintered Porous Wicks

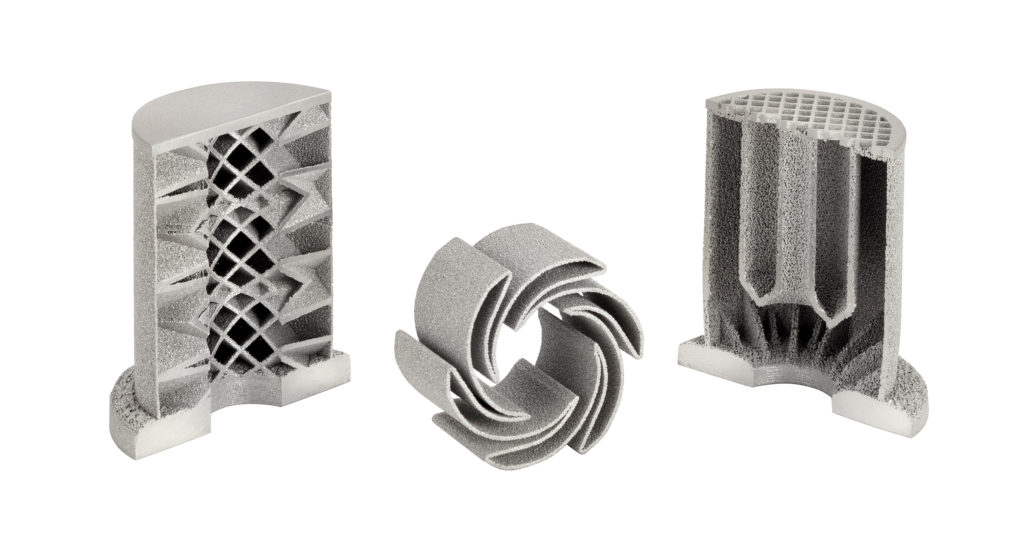

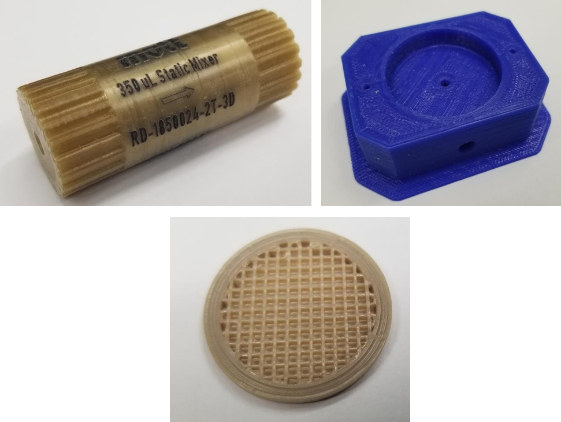

- 3D Printed Products

- Fluid Process Equipment

- Thermal Management Heat Pipe

- Fluidizers & Snubbers

Our Design Process

- Idea

- Design

- Prototype

- Analysis

- Production

- Optimization

Idea

Engineers and scientists are always breaking new technology barriers but getting an innovative idea off the ground takes the right partner. Our applications and design engineering teams work with you to understand your exact goals.

Design

When your specifications are clarified, our design team gets to work. Finding innovative ways to achieve breakthrough performance requires a balance of creativity and modeling simulation. Collaborating engineer to engineer is our standard operating procedure as we iron out the details.

Prototype

We aim to build prototypes QUICKLY at our Innovation Center where your design is brought to reality for the first time. Harness our rapid prototyping capabilities and extensive network of manufacturing and material partners and rest assured your product is built right – even in the face of the toughest specifications.

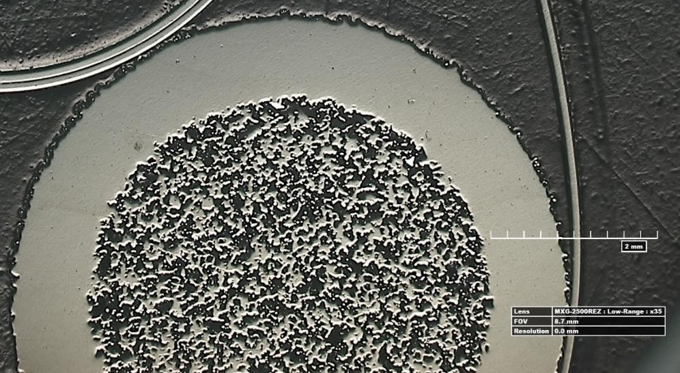

Analysis

Prototypes are only half of the equation – they require proof! Your products are verified and tested in our extensive lab facility located in our Customer Innovation Center where rigorous analysis and simulation testing validate that the product meets performance expectations. You will even get a complete data package showing test results.

Production

Once you’re confident the product meets the proper design and it’s fully approved, we’ll lock in specifications and manufacturing processes and proceed to production. The transition from prototype to high volume production will be seamless. We strive for 100% on-time delivery with lead times that are three times shorter than industry norms. Our ironclad quality is 100% guaranteed.

Optimization

The world is constantly changing. Keep pace with your customers’ needs by taking advantage of new features and higher levels of performance. We’re always available to enhance performance and achieve new levels of efficiency. Even before your product reaches its full potential, we’re ready to engage on its next iteration as we pursue an unending quest for excellence.